Handling the Production BOM When ECN Effectivity is Used to Exhaustion

There are times when an ECN effectivity says to use up existing parts before using the new parts (Use to Exhaustion). In Dynamics NAV, we have the option to phase in using “starting dates” and “ending dates” in Production BOM’s, but that is based on an estimated usage rate that may not be accurate.

There is a trick that will aid in planning for the new parts and using up the old parts. This trick may not be useful in a large company with rigid ISO procedures, but will work great in smaller companies.

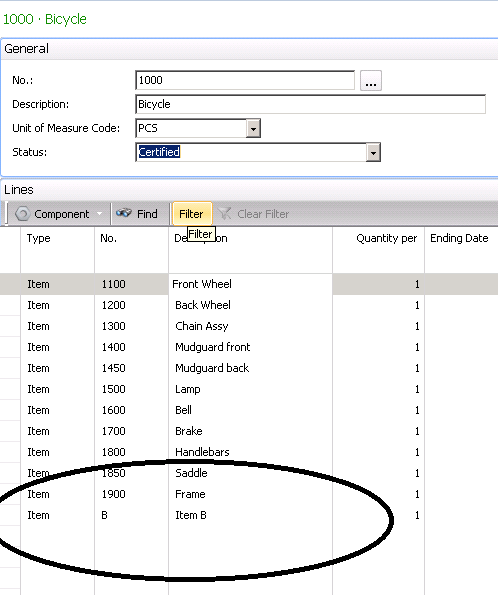

To Illustrate I have set up Item A and Item B. At this point they are both coded at “Purchased”. The ECN says to use up the stock of Item A before starting to purchase Item B.

Figure 1 – Two item cards, Item A and Item B

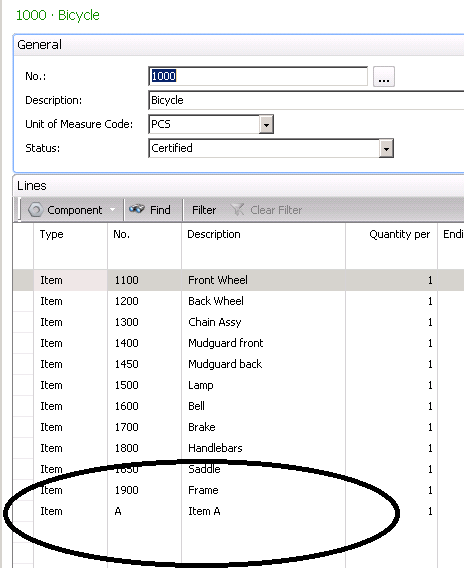

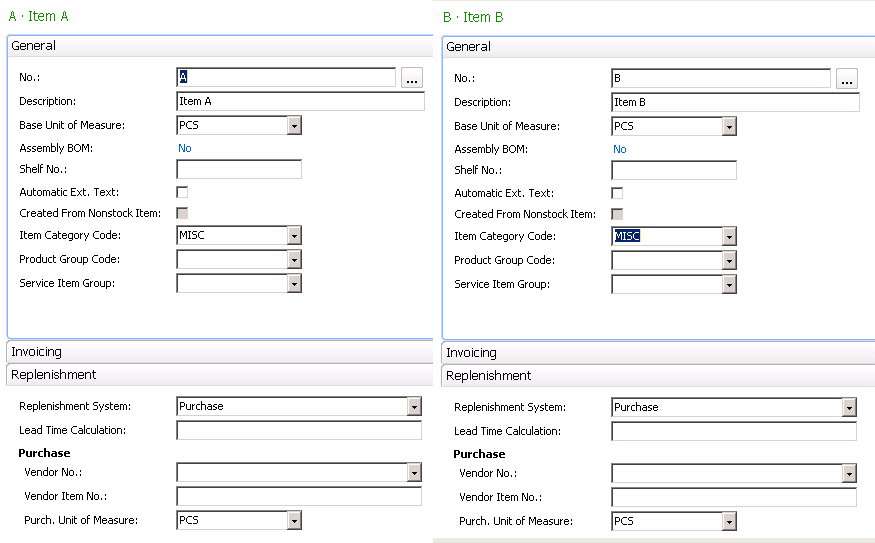

The figure below shows the Production BOM for Item 1000 call for Item A.

Figure 2 – Production BOM for Item 1000 call for Item A

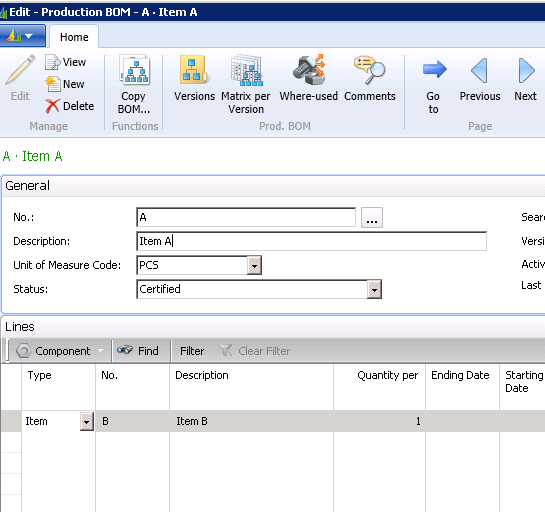

I set up a Production BOM for Item A that calls for Item B.

Figure 3 – Production BOM for Item A that calls for Item B

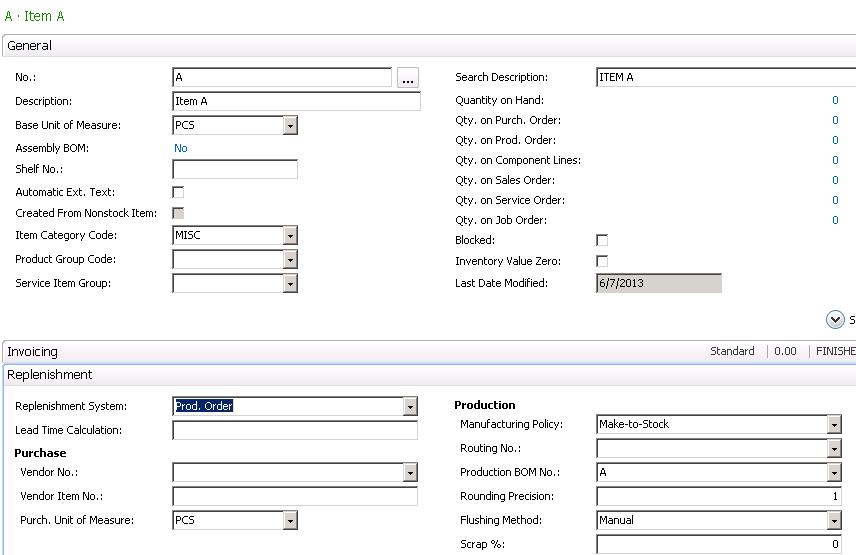

I then changed the “Replenishment System” for Item A to “Prod. Order”.

Figure 4 – Change the Replenishment System for Item A to Prod. Order

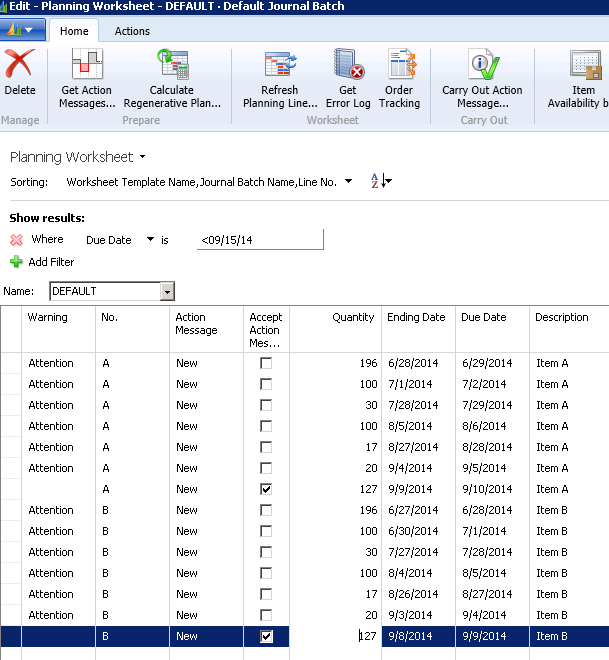

When I run MRP (Calculate Regenerative Plan), I get Action Messages to produce A and buy B. The planner will ignore the Action Messages to produce A, but will accept the Action Messages to buy B.

Figure 5 – Run Calculate Regenerative Plan on the Planning Worksheet

When the entire inventory for Item A is used up, the planner will change the Production BOM for Item 1000 to use Item B instead of A.

Figure 6 – The planner changes the Production BOM for Item 1000 to use Item B instead of A

If you would like more information on this subject or another Dynamics NAV subject, please contact ArcherPoint.

Read more “How To” blogs for practical advice on using Microsoft Dynamics NAV.

Trending Posts

Stay Informed

Choose Your Preferences

"*required" indicates required fields