Managing Scrap Effectively in Manufacturing with Microsoft Dynamics 365 Business Central

Scrap is an unavoidable reality in manufacturing. Whether it’s material waste, defective outputs, or inefficiencies during production, scrap needs to be carefully tracked and accounted for. Properly managing scrap helps manufacturers improve costing accuracy, plan more effectively, and uncover opportunities for process improvements.

Traditionally, scrap can occur at two stages: input scrap—loss or wastage of raw materials—and output scrap—defective or unusable finished goods. Accurately recording both types is crucial for maintaining profitability and meeting quality standards. Many manufacturers struggle with this process because it can become complex quickly, especially when dealing with multi-step production orders and variable material yields.

Fortunately, Microsoft Dynamics 365 Business Central offers a streamlined and flexible way to account for both input and output scrap.

How scrap is handled in Dynamics 365 Business Central

In Business Central, scrap is recorded directly during the manufacturing process, allowing you to track losses and make planning adjustments in real time. There are two main aspects of scrap accounting in Business Central: actual scrap recording and planned scrap consideration.

Recording actual scrap during production

You can record scrap at any output operation step when executing a production order. For example, if a production process has five steps, you can log scrap at each step using either an Output Journal or a Production Journal. This gives you detailed visibility into where scrap occurs during the manufacturing process.

To access the Output or Production Journal, go to Production Orders > Select an Order > Line > Output Journal or Production Journal.

Key capabilities include:

- Recording the quantity scrapped – Enter the amount of defective output produced at any stage.

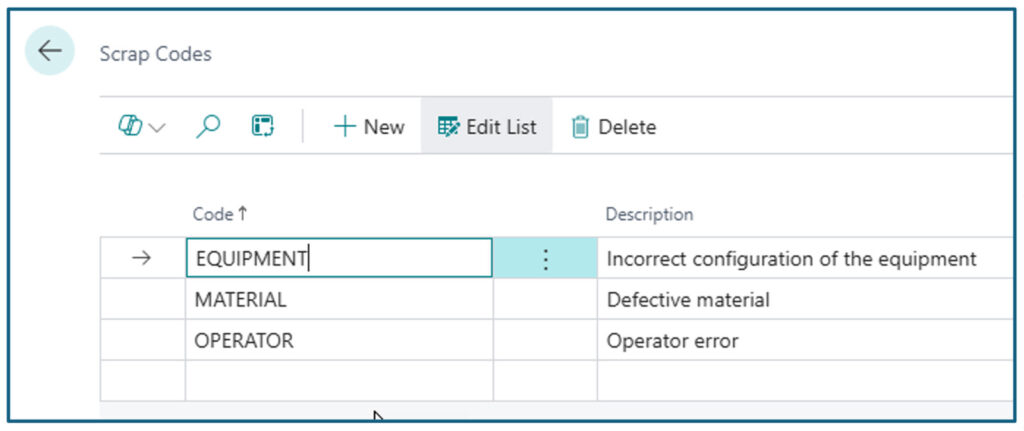

- Assigning scrap codes – To provide context, Business Central lets you use scrap codes to categorize the reason for scrap (e.g., material failure, machining error, operator mistake). Scrap codes are user-defined, giving you flexibility to align with your internal quality management practices. To enter scrap codes, go to Manufacturing Setup or search for Scrap Codes directly.

Backward flushing

Recording scrap does not affect raw material consumption if the Flushing Method on the component Item Card is Forward or Manual. However, if the Flushing Method is Backward, Business Central automatically adjusts material consumption based on the output quantity and the scrap quantity that is recorded.

For example, suppose you need one chassis for every finished item, and the item is backflushed. At the last operation, the user outputs four units and reports one scrap unit. The system will backflush five units using this equation:

Consumption Qty = Qty per Unit of Measure * (Output Qty + Scrap Qty)

By default, backward flushing occurs at the final operation. However, if the Prod. Order Component record is associated with a Routing Operation using a Routing Link Code, Business Central will calculate the consumption quantity using the output and scrap quantities recorded at the operation.

Planning for expected scrap

In addition to recording actual scrap during production, Business Central allows manufacturers to plan for expected scrap during material planning and costing processes.

You can define scrap percentages at three different levels:

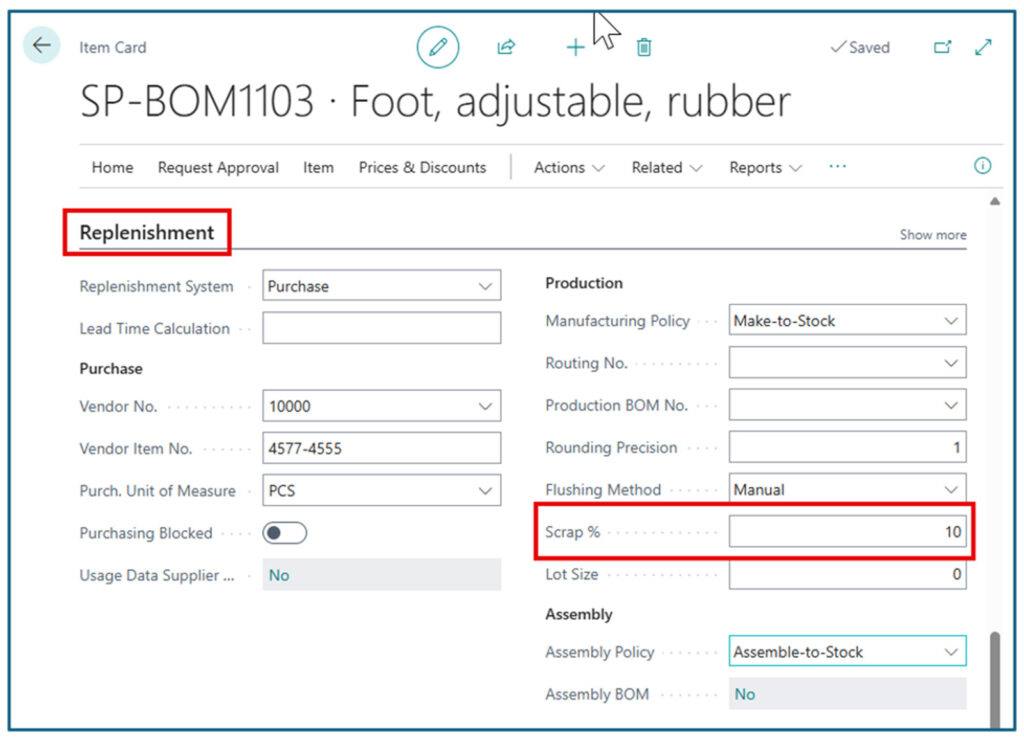

Item Card – Set a general scrap percentage for a raw material item (e.g., if capacitors have a 10% expected failure rate regardless of how and where they are used). To access the Item Card, go to Items > Select an Item > Item Card.

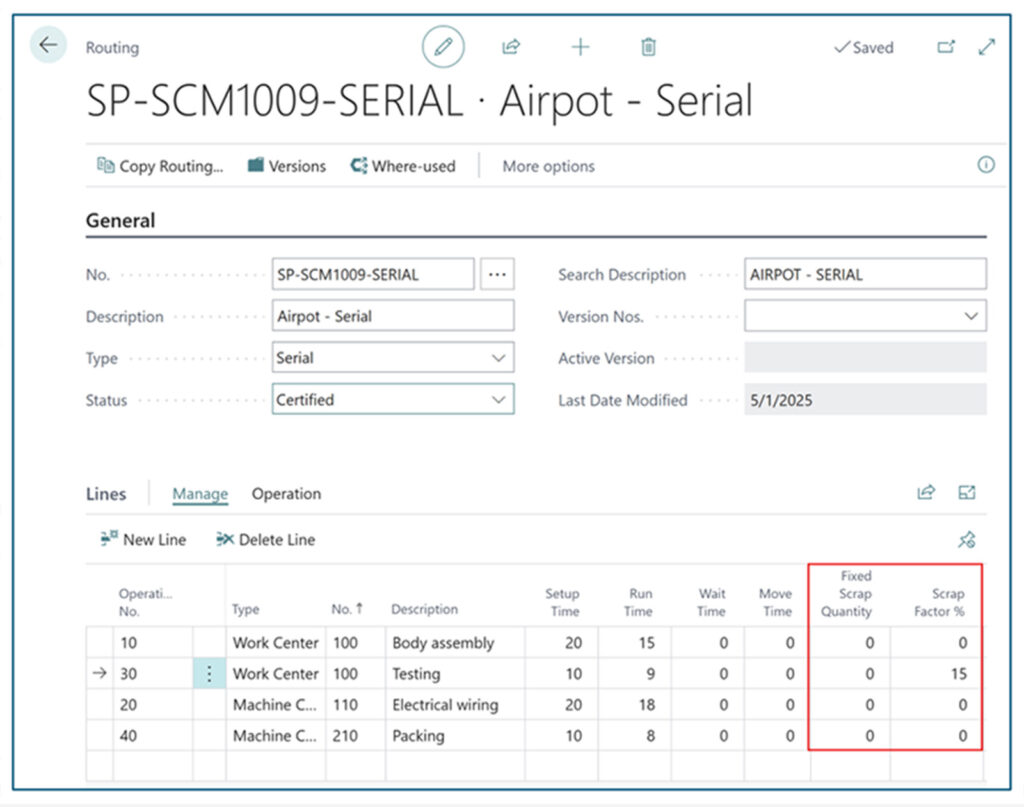

Routing Line—Set an expected loss for a specific production operation (e.g., losing 10% yield during a heat-treatment step). To access the Routing Lines, go to Routings > Select a Routing > Routing Lines. The Routing Line also permits the user to specify a Fixed Scrap Quantity. This is typically used when a piece is scrapped during production (e.g., during a printing operation, the first piece is run as a test piece to be scrapped).

Production Bill of Materials (BOM) line – Define scrap expectations for a particular raw material when producing a specific finished good. To enter the scrap expectation for a component, go to Production Bill of Materials (BOMs) > Select a BOM > BOM Lines.

When planning material requirements (via planning worksheets or requisitions), Business Central automatically adjusts quantities upward to account for the scrap percentage. For example, suppose you produce ten units and expect a 10% scrap rate for a component. In that case, Business Central will plan for eleven components to ensure you have enough to meet production goals even after accounting for failures.

This planned overage feeds into purchasing and inventory management processes, helping you avoid last-minute shortages while maintaining better cost control.

Variance Handling

If you plan for a certain level of scrap but experience less scrap than expected, this results in a positive production variance, meaning your production was more efficient than planned. Conversely, having more scrap than anticipated results in a negative variance, impacting your production costs.

Business Central’s costing methods (such as Standard Costing) and variance analysis tools allow you to track these discrepancies closely, giving you greater insight into production efficiency and opportunities for continuous improvement.

A note on material loss and rounding precision

It’s important to distinguish between scrap and planned material usage inefficiencies. For example, suppose you’re cutting lumber and always have leftover waste (e.g., a two-foot piece from a ten-foot board). In that case, that scenario relates to rounding precision settings rather than scrap accounting. Rounding ensures full consumption of units based on packaging, material sizes, or standard cuts.

Understanding this distinction helps ensure that scrap tracking focuses on production quality issues while material loss planning remains part of item consumption strategies.

Effective scrap management is essential for any manufacturing operation seeking to maintain profitability, improve planning accuracy, and drive operational excellence. Microsoft Dynamics 365 Business Central offers a robust yet flexible framework for handling both real-time scrap recording and scrap planning, giving manufacturers a powerful advantage.

Ready to optimize your manufacturing processes?

If your current manufacturing system makes it difficult to track or manage scrap accurately, it’s time to explore how Business Central—and the right implementation partner—can help.

ArcherPoint specializes in helping manufacturers unlock the full potential of Microsoft Dynamics 365 Business Central. From production planning to scrap management and beyond, we bring deep industry expertise and proven best practices to every project.

Contact ArcherPoint to schedule a consultation and learn how we can help you streamline production, reduce waste, and improve your bottom line.

Trending Posts

Stay Informed

Choose Your Preferences

"*required" indicates required fields