Using Phantom BOMs in Business Central to Streamline Manufacturing

In manufacturing, the Bill of Materials (BOM) defines the items, parts, assemblies, and sub-assemblies required to create a finished product. These components are often discrete items and sub-assemblies purchased or manufactured and placed in inventory for later use.

A phantom BOM represents the elements that are used to create a sub-assembly that is an essential part of the completed product but never exists in inventory. Instead, it is assembled and used immediately while manufacturing the finished product.

Why use phantom BOMs

- Streamlined production orders – Phantom BOMs help streamline the manufacturing process by treating a group of elements as a single entity.

- Design flexibility – Phantom BOMs can be modified without affecting other BOMs used in manufacturing the final product, accommodating greater design flexibility.

- Reduced inventory management – Since the phantom BOMs do not create a physical item in inventory, they help reduce the need to carry and account for the sub-assemblies in inventory.

Creating a phantom BOM in Dynamics 365 Business Central

To create a phantom BOM in Business Central:

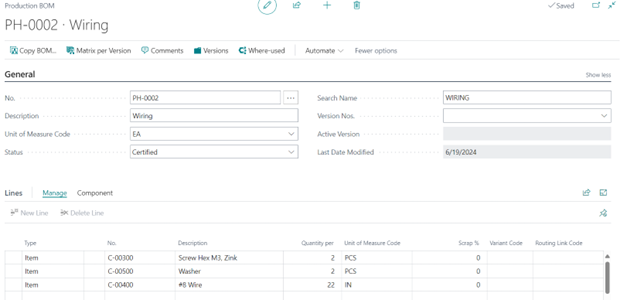

1. Go to the production BOM card and create a new BOM. Enter the components and quantities like any other BOM, then certify. There is no need to associate this BOM with an inventory item. NOTE: A separate numbering series can be used to differentiate phantoms from your other BOMs (for example, a prefix of “PH-“).

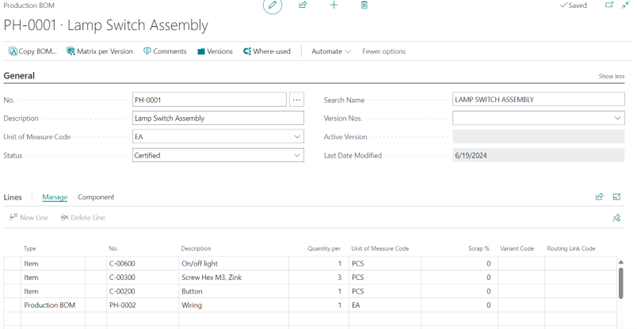

2. You can have multiple levels of phantom BOMs on a production BOM or within another phantom BOM. Add the phantom BOM to another BOM by setting the component line > Type to Production BOM rather than Item.

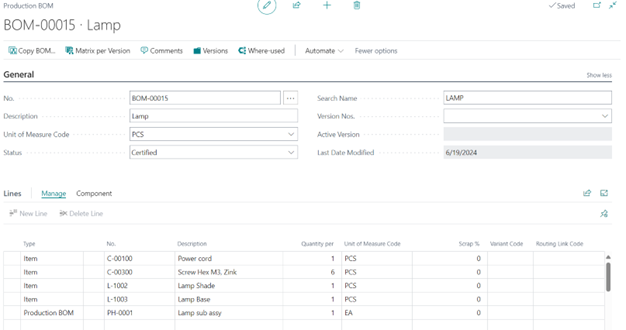

3. Add the Phantom BOM(s) to the Production BOM (i.e., the BOM associated with a finished item).

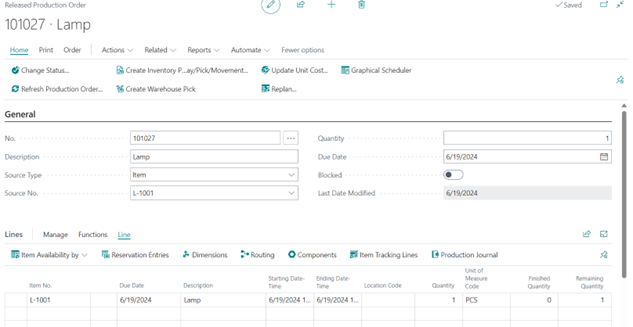

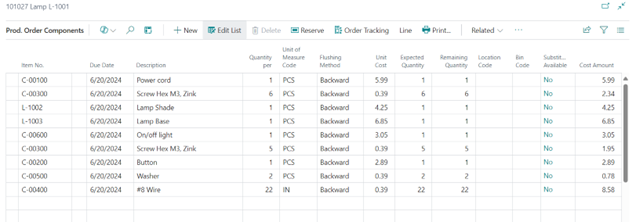

4. When a production order is created for the top-level finished goods, the components for all BOM levels are listed in production order components.

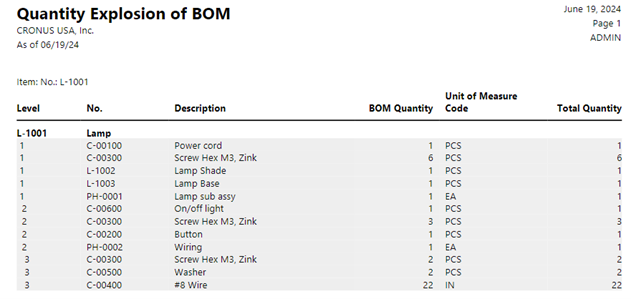

5. Run Quantity Explosion of BOM report to get an indented version of components by level to check your work.

Phantom BOM use cases

Phantom BOMs are versatile tools that have many applications in manufacturing:

- Create product variants – In cases where a product offers several variants or customizations, phantom BOMs can be used to specify the various combinations of configurable options. For example, a computer manufacturer might create a base product. Then phantom BOMs can be created to specify customizable options such as RAM, storage, and processor. The manufacturer can now manage the base product and configurable options separately.

- Group commonly used components across products – When multiple parts are used across various products, they can be grouped together in a phantom BOM to facilitate production scheduling. For instance, a furniture manufacturer might use phantom BOMs to group items like legs, fabric, nails, and screws. Treating these items as a single unit reduces the complexity of managing the production timeline.

- Facilitate Just-in-Time manufacturing — Since phantom items are created during the manufacturing process, the constituent parts are available when needed but never added to inventory. This helps reduce holding costs and supports lean manufacturing practices.

Contact ArcherPoint to learn more about how Phantom BOMs can be used in Dynamics 365 Business Central to help your company streamline manufacturing processes, improve production scheduling, and control costs.

Trending Posts

Stay Informed

Choose Your Preferences

"*required" indicates required fields