Electronic Data Interchange (EDI): What Is It and Why Does It Fail?

Manufacturing and distribution companies rely on Electronic Data Interchange (EDI) to streamline business-to-business communication. For companies working with major retailers like Walmart, Amazon, or Target, EDI isn’t optional—it’s a requirement. But while EDI promises automation and efficiency, many companies are frustrated by failed transmissions, costly chargebacks, and missing payments. Why does this happen?

What is EDI?

EDI provides a standardized method for businesses to exchange information electronically—like purchase orders, invoices, and shipping notices—without manual intervention.

Instead of emailing PDFs or typing order details into a portal, EDI allows systems to communicate with each other using agreed-upon transaction formats. For example:

- An 810 is an Invoice.

- An 850 is a Purchase Order.

- An 855 is a Purchase Order Acknowledgment.

- An 856 is an Advance Shipping Notice (ASN).

This process is designed to be fast, accurate, and consistent. So why does it fail so often?

The hidden complexity behind a “simple” concept

EDI may sound straightforward—sending and receiving data between systems—but in practice, it’s anything but.

While the concept is simple, the implementation is complex. That’s because EDI requires absolute consistency in how data is formatted, cross-referenced, and validated. A missing customer number, an incorrect unit of measure, or an improperly formatted date can cause an entire order to fail—or worse, be processed incorrectly.

Key reasons why EDI fails

No single source of truth

One of the biggest pitfalls in EDI implementations is data duplication between systems. Ideally, your ERP (like Microsoft Dynamics 365 Business Central or NAV) should be the single source of truth. However, most EDI solutions live outside of the ERP, forcing businesses to maintain data (like cross-references, customer codes, and shipping units) in two places: the ERP and the EDI software. This creates room for discrepancies—and when they happen, it’s not always obvious until a trade partner rejects an order or issues a chargeback.

Lack of built-in validation or error handling

Most EDI solutions simply extract data from the ERP and transform it into a format like X12. But this process often lacks validation logic—rules that check for blank values, incorrect formats, or conditional dependencies (e.g., if it’s a freight shipment, include a bill of lading number). Without these safeguards, bad data flows downstream, and the EDI software, unaware that something’s missing or incorrect, sends it anyway. That means the first time you realize something went wrong is after the invoice doesn’t get paid or you receive a costly chargeback—which can be as much as $500 per sales order.

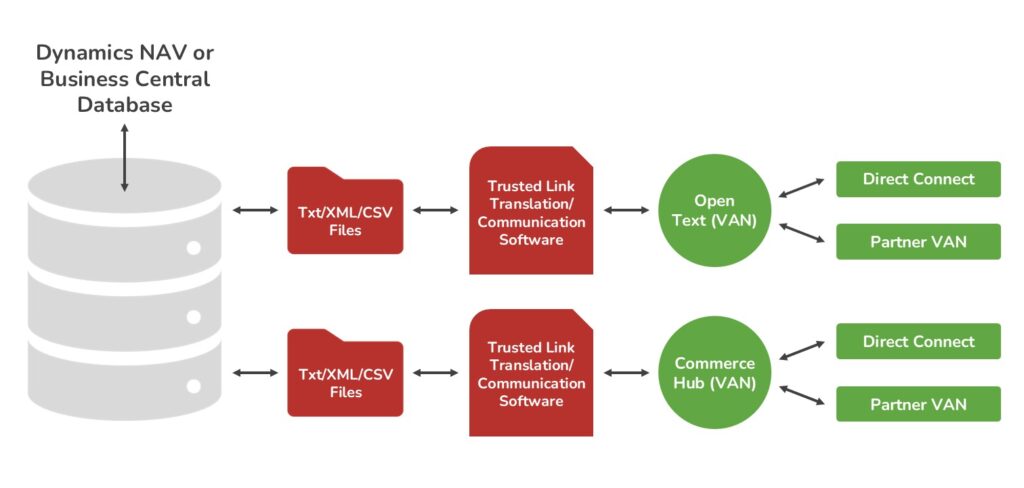

Double translation

With most EDI solutions, data goes through two translation steps:

- From the ERP (e.g., Business Central) to a flat file (XML, CSV, TXT).

- From that file into an X12 or EDIFACT format for the trading partner.

Each step introduces more complexity—and more chances for miscommunication. It’s like playing the telephone game: the more times a message is passed along, the more likely it is to be distorted.

Disconnected systems = poor visibility

When EDI systems live outside the ERP, users must log into a separate portal to monitor errors, send documents, or review logs. This creates extra steps, delays issue resolution, and leads to missed documents—especially if no one is actively checking the portal. This lack of visibility makes it difficult to audit transactions. When the EDI lives outside the ERP, the user must log into the EDI software portal and search through the many files to verify the records or correct errors.

Making matters worse, most users aren’t trained on how EDI works. They simply assume it’s “taken care of,” and they don’t know where to start troubleshooting when problems arise.

Lack of standardization (despite the name)

EDI is supposed to be a standard, but in reality, every trading partner has its own variations. A one-size-fits-all map doesn’t cut it. Each partner may require slightly different document structures, values, and timing. Trying to use a single mapping for all partners often leads to errors—and unless your EDI solution allows for custom mapping per partner, you’re stuck trying to force data into formats that don’t match.

So, what’s the fix?

To reduce EDI failure rates, businesses need to:

- Centralize data management within the ERP.

- Implement validation rules that check for missing or incorrect fields before data is transmitted.

- Use EDI tools that integrate directly with your ERP, not outside of it. This reduces duplication, allows real-time error checking, and helps prevent costly mistakes before they happen.

- Ensure visibility into what’s being sent, what failed, and why.

- Train internal teams to understand how EDI works and where issues can arise.

Need help implementing EDI? Talk to the experts at ArcherPoint!

EDI can be a powerful tool for automation and scale—but only if it’s implemented properly. Businesses that treat EDI as a black box often get burned by failed orders, missed payments, and lost trust with trading partners.

If your EDI system feels like a mystery—or a recurring source of costly headaches—it might be time to rethink your setup. Contact the EDI experts at ArcherPoint by Cherry Bekaert to learn how we can help you get EDI working for you, not against you!

Trending Posts

Stay Informed

Choose Your Preferences

"*required" indicates required fields