How to Cycle Count in Microsoft Dynamics NAV, Part 2

In a previous blog, How to Cycle Count in Microsoft Dynamics NAV, Part 1: Counting by ABC Classification, we discussed how to cycle count using Classification codes in Microsoft Dynamics NAV. This blog walks through the cycle count process when using the count by warehouse location and how to use NAV to do so.

To review, cycle counting is NOT a tool to count your way to inventory accuracy. Inventory accuracy is the result of sound inventory processes and procedures. If you have poor processes and procedures, you will always have inaccurate inventory no matter how many times you count it. The real purpose of a good cycle count program is to identify your poor inventory practices so that they can be corrected. Continuously improving inventory practices will lead to continuously more accurate inventory.

There are two approaches to Cycle Counting:

- Count by ABC classifications: This method breaks items into categories of importance and count the more important items more frequently. (Note: this method was discussed in the previous blog).

- Count by location in the warehouse: This method breaks the warehouse into sections, and the counting moves from section to section, and then starts over at the first section again.

Of course, there can be variations to this logic, where the warehouse sections have been broken into categories and the A sections counted more frequently than the B and C sections. NAV can easily work with the first two methods of cycle counting. More advanced cycle counting could be done, but the assigning and tracking would need to be done outside of NAV.

This blog discusses how to cycle count in NAV using the Location in Warehouse method.

Cycle count by location in warehouse

This cycle count method cycles through the warehouse bins by area. The benefit to this approach is that you count all bins and adjust inventory that has been “misplaced.” The ABC Classification method does not find misplaced product as it requires that you count product where the system knows it exists. If an item has been placed in the wrong bin, then cycle counting by classification will not find these errors directly.

The first step when cycle counting by physical location is to break the warehouse into counting sections. There is no specific guidance to this except to make the volume of bins to count achievable in the counting time frame. If bins are counted daily, then the number of bins in the count section must be able to be counted during the daily count period.

The cycle counting process is quite simple in that the bins are selected as filters when the count sheets are created.

Selecting parts to count

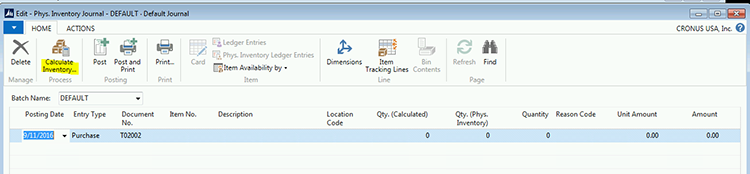

- NAV uses the Physical Inventory Journal to generate cycle counts. Open the Physical Inventory Journal and select the Calculate Inventory function on the Action tab.

Figure 1. Physical Inventory Journal with Calculate Inventory function highlighted.

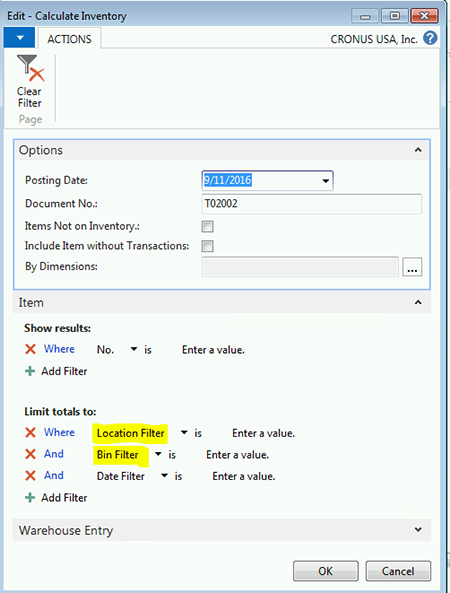

- Once this option has been selected, NAV will display an options selection page.

Figure 2. Options Selections page.

- The user would use the location and bin filter fields to select the bins that are to be counted.

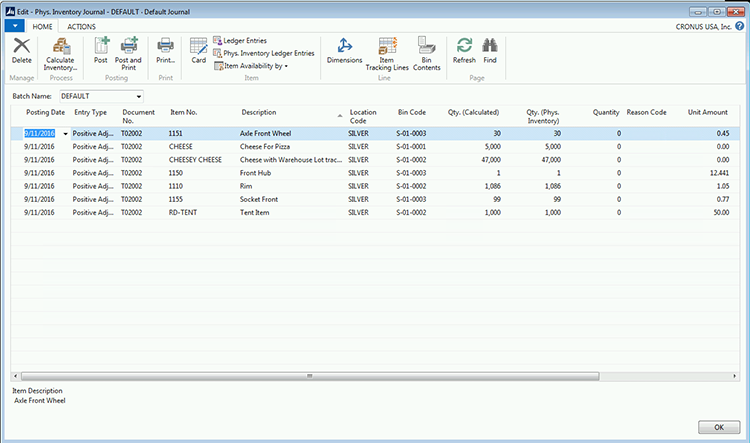

- The journal is populated with items that exist in the bins that were selected.

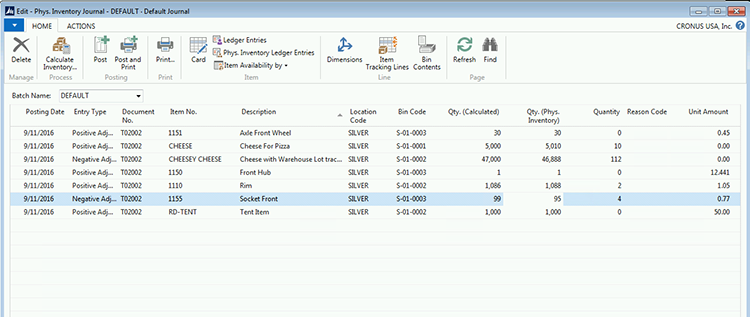

- In the example below, the location filter was “Silver.” The bin filter was S-01-0001..S-01-0003. Note that the only count lines on the count sheet are within this filter range.

Figure 3. Physical Inventory Journal with location filter.

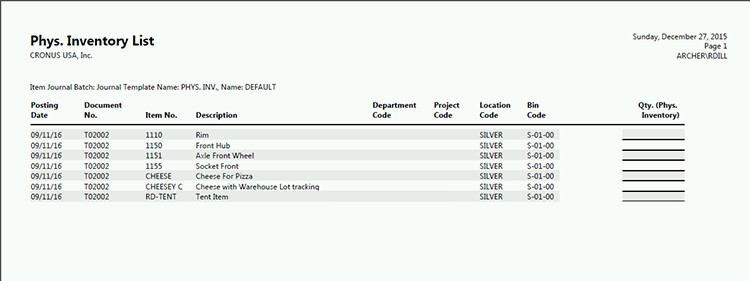

- Print the count list by clicking on the Print icon on the ribbon.

- A sample of the print is shown below.

Figure 4. Physical Inventory List printout.

- Once the item has been counted, record the count in the “Qty. (Phy. Inventory)” column as shown below.

Figure 5. Recording the count in the “Qty. (Phy. Inventory)” column.

- NAV calculates the difference between the Quantity Counted and the Quantity on Hand, and populates the “Quantity” field.

- When this is posted, NAV will adjust the inventory.

NAV does not track the counting of the bins, as this is a bin property rather than an item card property. This process will work, but the counting by bin range will need to be defined and tracked outside of NAV.

Remember that the most important part of the cycle count process is to identify why the error exists. Any error should be researched to find out why the error existed. Once the reason is known, you can track the cause of the error and record it in the Reason Code field on the journal line. This will allow you to track the most frequent errors and make procedural changes that will eliminate these errors.

If you have any questions about this blog, contact ArcherPoint.

Related to this topic:

Setting Up Cycle Counting with Warehouse Management in Dynamics NAV

For more step-by-step instructions on how to perform specific tasks in Microsoft Dynamics NAV, see our collection of How-To blogs.